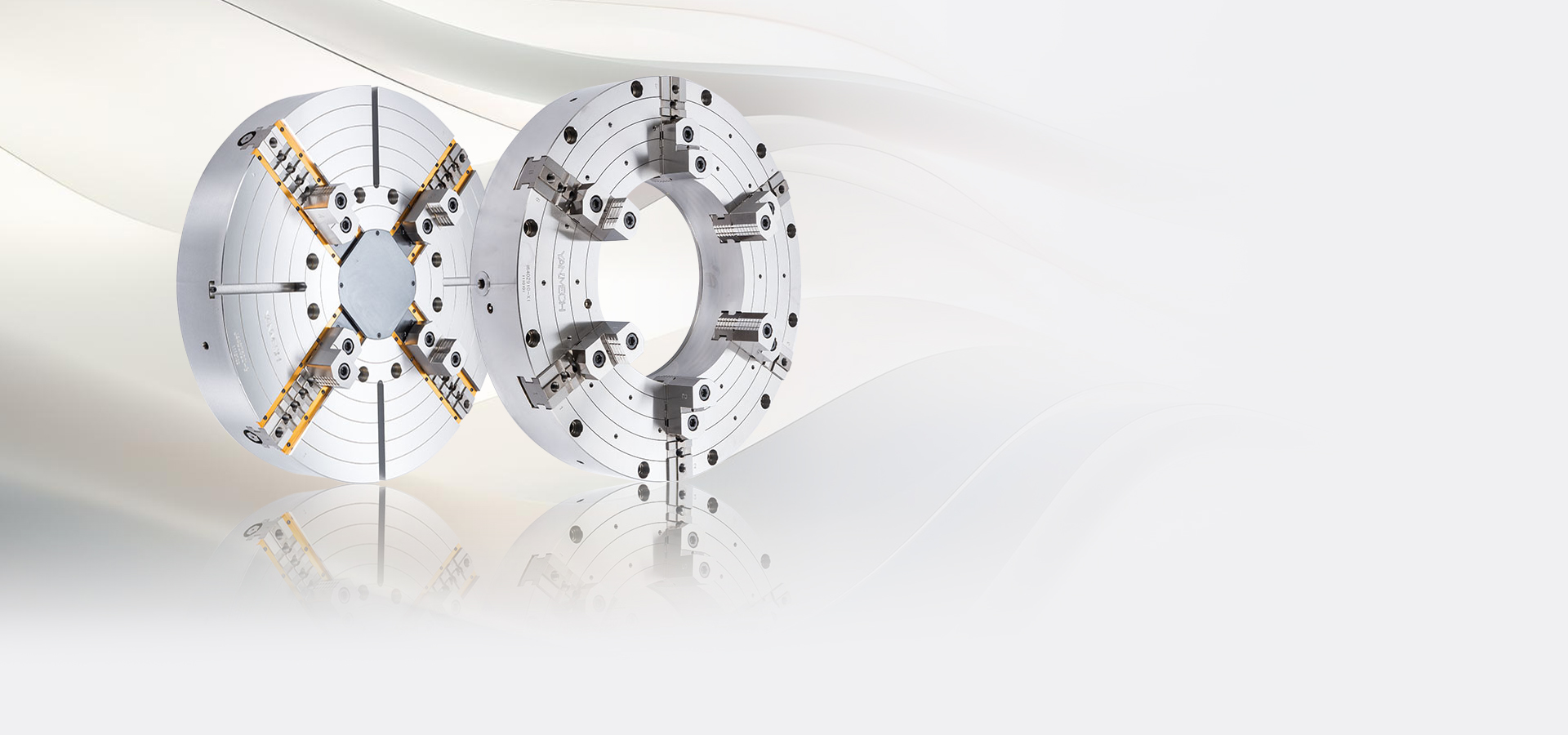

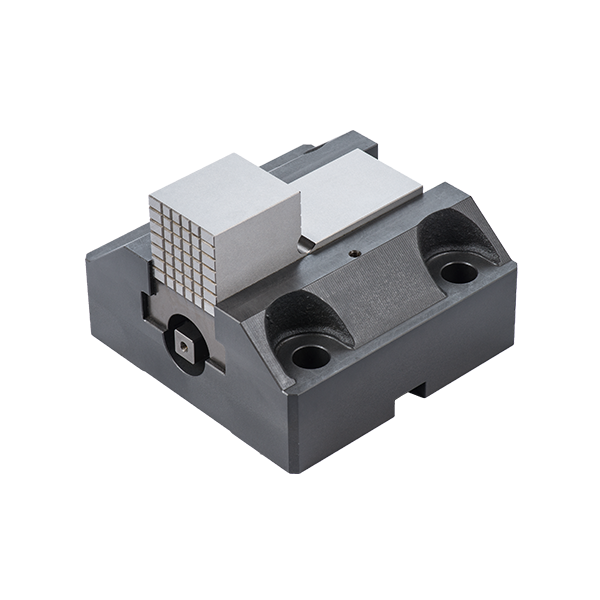

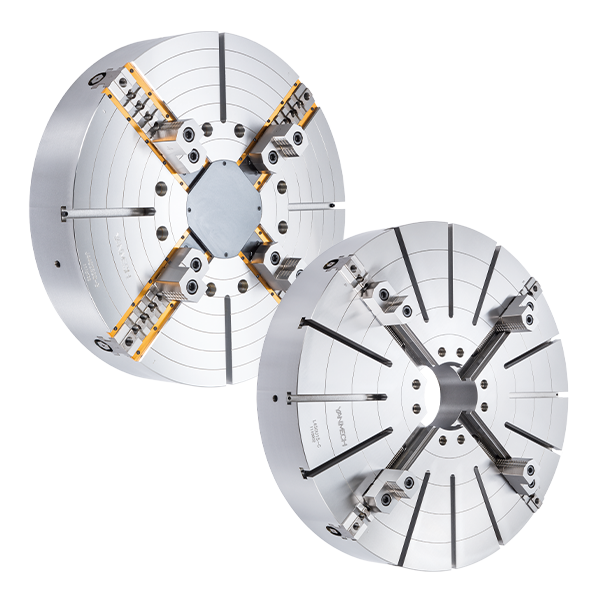

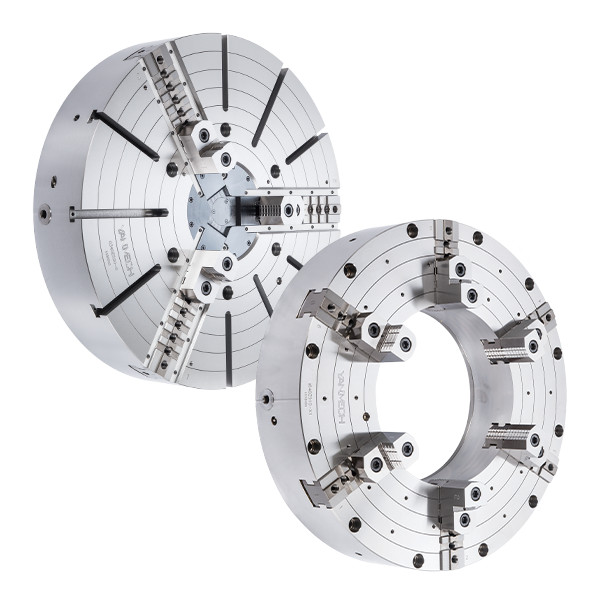

Application

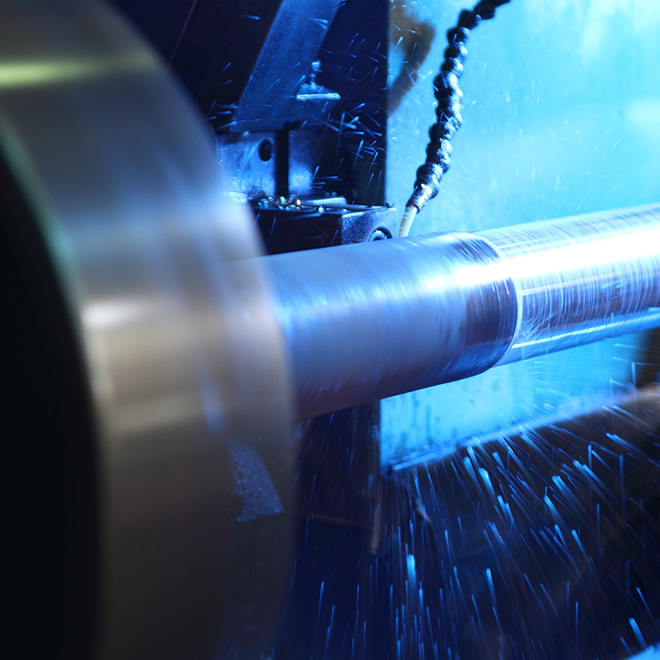

A chuck is a critical component used to secure workpieces or tools. Leveraging years of experience, YANMECH Industrial has recently invested in the development and manufacturing of its own brand of chucks. We have rapidly introduced a variety of high quality chuck products to meet diverse needs. We provide tailored solutions for different machinery, ensuring the best fit for your equipment.

LEARN MORE