Milling Machine

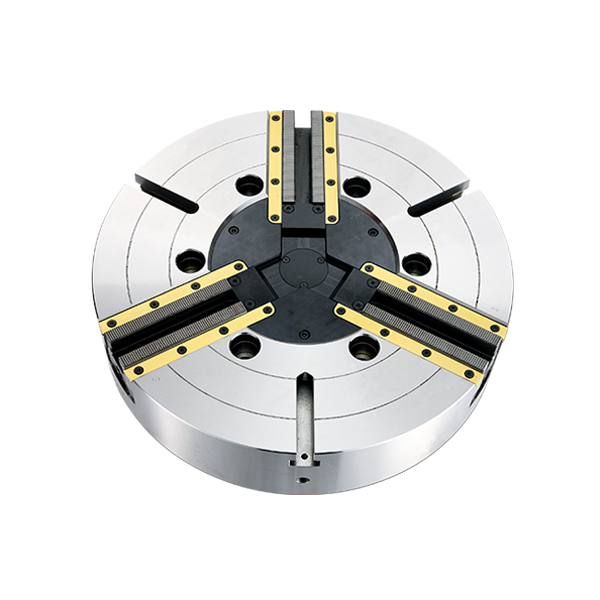

A milling machine is used to move a cutting tool across a workpiece to cut material, thereby creating the desired shape. Chucks can be used to secure the cutting tool or workpiece, making the cutting process more stable and precise.

⊙ Chucks play an important role in milling machine operations, one of their main uses being to secure cutting tools. Tools on a milling machine are mounted on a tool holder or spindle, and chucks are responsible for firmly fixing the tools in the correct position and angle, ensuring stability and accuracy during the cutting process.

⊙ Milling machines typically have multiple axes of motion, such as X, Y, and Z axes. Chucks can be used to secure the workpiece, keeping it stable during the cutting process. This ensures that the tool can move accurately over the surface of the workpiece, cutting out the desired shape.

⊙ In some special cases, chucks can also be used to secure and hold attachments or tools other than cutting tools, such as drill bits and fixtures. These attachments are often used for auxiliary operations, such as drilling and clamping workpieces.

⊙ The design of chucks on milling machines is diverse, allowing for the selection of a suitable chuck based on specific machining needs. Some chucks have adjustable features, enabling operators to adjust the clamping force according to the shape and size of the workpiece, ensuring that the workpiece does not move or wobble during cutting.

⊙ The stability and precision of chucks are crucial to the success of milling machine operations. Proper clamping ensures the production of high-quality, accurate parts and workpieces, while also improving operational efficiency and safety.

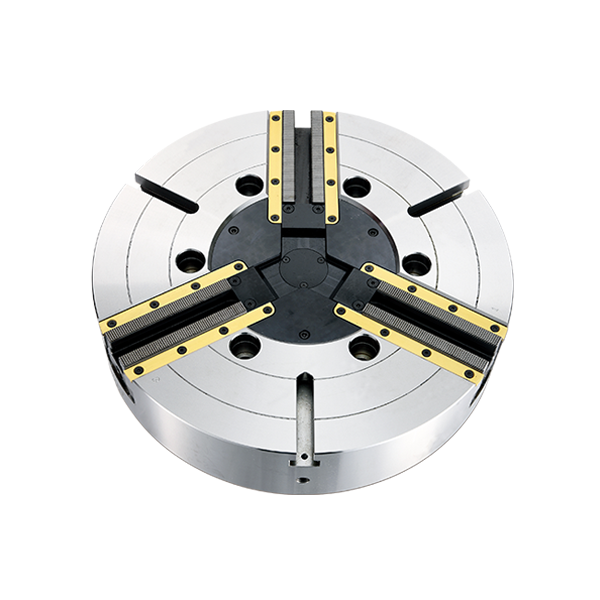

⊙ Chucks play an important role in milling machine operations, one of their main uses being to secure cutting tools. Tools on a milling machine are mounted on a tool holder or spindle, and chucks are responsible for firmly fixing the tools in the correct position and angle, ensuring stability and accuracy during the cutting process.

⊙ Milling machines typically have multiple axes of motion, such as X, Y, and Z axes. Chucks can be used to secure the workpiece, keeping it stable during the cutting process. This ensures that the tool can move accurately over the surface of the workpiece, cutting out the desired shape.

⊙ In some special cases, chucks can also be used to secure and hold attachments or tools other than cutting tools, such as drill bits and fixtures. These attachments are often used for auxiliary operations, such as drilling and clamping workpieces.

⊙ The design of chucks on milling machines is diverse, allowing for the selection of a suitable chuck based on specific machining needs. Some chucks have adjustable features, enabling operators to adjust the clamping force according to the shape and size of the workpiece, ensuring that the workpiece does not move or wobble during cutting.

⊙ The stability and precision of chucks are crucial to the success of milling machine operations. Proper clamping ensures the production of high-quality, accurate parts and workpieces, while also improving operational efficiency and safety.