Gun Drilling Machine

Gun Drilling Machine and Deep Hole Drilling Machine typically use fixtures or clamping heads to ensure the stability and accuracy of workpieces during machining. The design of these fixtures usually considers the shape, size, and machining requirements of the workpieces to ensure safety and efficiency during machining.

Some common applications of fixtures or clamping heads in boring machines and deep hole drilling machines include:

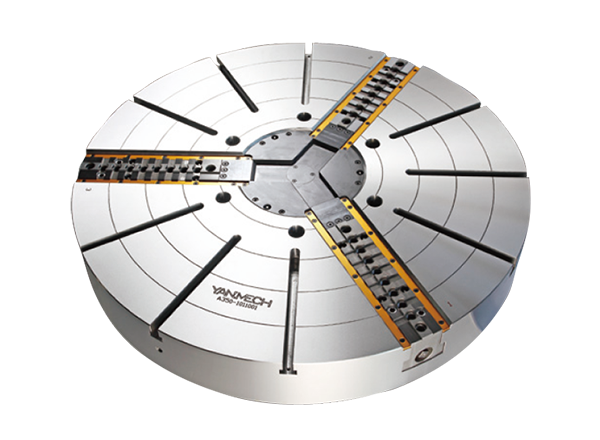

⊙ Clamping of workpieces: During boring or deep hole drilling, workpieces need to be clamped on the machine's worktable or fixture to ensure their stability during machining. Fixtures or clamping heads can provide the necessary clamping force to prevent workpiece movement or vibration.

⊙ Workpiece positioning: Fixtures or clamping heads can also be used to position workpieces to ensure they are placed in the correct position to meet machining accuracy and requirements, especially in precision machining.

⊙ Support for long workpieces: In deep hole drilling, when the workpiece is long, support devices may be needed to prevent bending or deformation during machining. Fixtures or clamping heads can provide support to ensure the workpiece maintains its desired shape.

⊙ Multi-workpiece machining: Sometimes, multiple workpieces need to be machined simultaneously to improve production efficiency. Fixtures or clamping heads can be designed to clamp multiple workpieces for batch production.

Overall, the use of fixtures or clamping heads in boring machines and deep hole drilling machines provides the necessary support and stability to ensure smooth machining processes and achieve the desired machining results.

Some common applications of fixtures or clamping heads in boring machines and deep hole drilling machines include:

⊙ Clamping of workpieces: During boring or deep hole drilling, workpieces need to be clamped on the machine's worktable or fixture to ensure their stability during machining. Fixtures or clamping heads can provide the necessary clamping force to prevent workpiece movement or vibration.

⊙ Workpiece positioning: Fixtures or clamping heads can also be used to position workpieces to ensure they are placed in the correct position to meet machining accuracy and requirements, especially in precision machining.

⊙ Support for long workpieces: In deep hole drilling, when the workpiece is long, support devices may be needed to prevent bending or deformation during machining. Fixtures or clamping heads can provide support to ensure the workpiece maintains its desired shape.

⊙ Multi-workpiece machining: Sometimes, multiple workpieces need to be machined simultaneously to improve production efficiency. Fixtures or clamping heads can be designed to clamp multiple workpieces for batch production.

Overall, the use of fixtures or clamping heads in boring machines and deep hole drilling machines provides the necessary support and stability to ensure smooth machining processes and achieve the desired machining results.