Welding Positioner

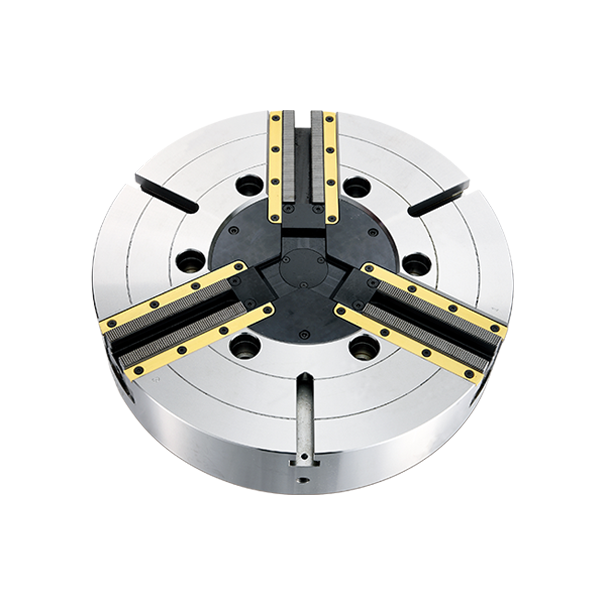

During the welding process, chucks are often used to secure or position the parts to be welded. Chucks play a very important role in welding, especially in ensuring that the weld joints are accurately aligned and securely fixed. Here are some common uses of chucks in welding:

⊙ Securing Workpieces: Chucks are used to secure smaller or lighter workpieces to prevent them from moving during the welding process, thereby ensuring the quality and precision of the weld seam.

⊙ Aligning Joints: When welding assemblies involving multiple parts, chucks help to precisely align the joints, ensuring that the positions of the components are correct during the welding process.

⊙ Reducing Deformation: Due to the high temperatures involved in welding, materials may undergo thermal expansion and deformation. Chucks can limit this deformation to some extent, ensuring that the dimensions and shape of the components meet requirements after welding.

⊙ Enhancing Safety: Chucks also enhance operational safety by preventing operators from having to hold or be near hot workpieces directly.

Therefore, chucks are indispensable tools in welding work. They not only improve the quality and efficiency of welding but also ensure the safety of operations. When selecting chucks, the choice is usually based on the material, shape, and size of the workpieces, as well as the specific requirements of the welding environment.

⊙ Securing Workpieces: Chucks are used to secure smaller or lighter workpieces to prevent them from moving during the welding process, thereby ensuring the quality and precision of the weld seam.

⊙ Aligning Joints: When welding assemblies involving multiple parts, chucks help to precisely align the joints, ensuring that the positions of the components are correct during the welding process.

⊙ Reducing Deformation: Due to the high temperatures involved in welding, materials may undergo thermal expansion and deformation. Chucks can limit this deformation to some extent, ensuring that the dimensions and shape of the components meet requirements after welding.

⊙ Enhancing Safety: Chucks also enhance operational safety by preventing operators from having to hold or be near hot workpieces directly.

Therefore, chucks are indispensable tools in welding work. They not only improve the quality and efficiency of welding but also ensure the safety of operations. When selecting chucks, the choice is usually based on the material, shape, and size of the workpieces, as well as the specific requirements of the welding environment.