PRODUCTS

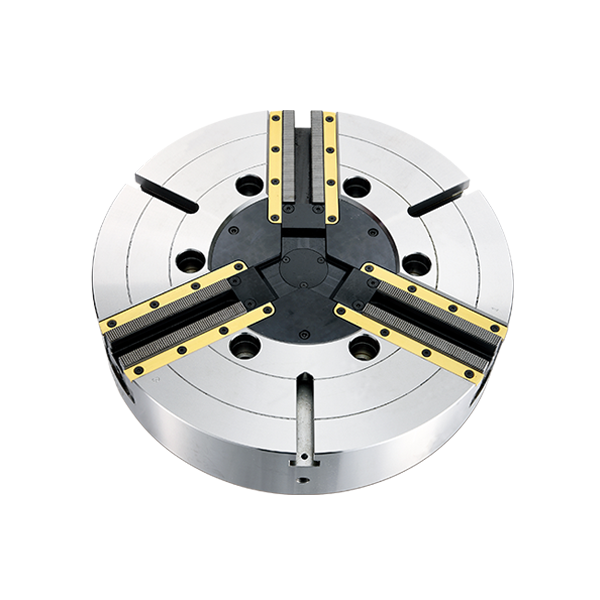

D series (Closed center high precision power chucks)

CLOSED CENTER HIGH PRECISION POWER CHUCKS

HYDRAULIC CHUCKS

Application

Lathe

Milling Machine

Grinding Machine

Milling Machine

Grinding Machine

Features

- Install side strips and chips cover sealed base jaw to prevent chips and coolant ingress.

- Adapter Plates can be selected.

- The base jaw is lower than the body surface and can be used for multipurpose.

- Alternative spindle adaptors: ASA or DIN adaptors can be supplied as requested.

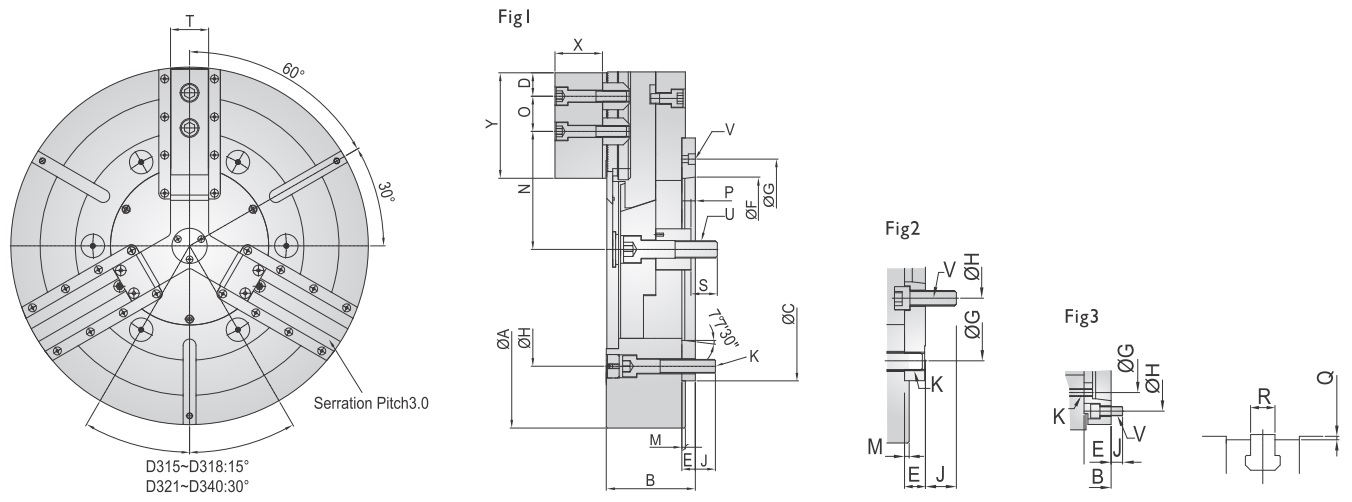

| Model | Adaptor | Plunger Stoke(mm) | Jaw Stoke [Diameter] (mm) | Max.Push Force (kgf) | Max. Gripping Force(kgf) | Max. Hydr. Pressure (kgf/cm²) | Max. Speed (r.p.m.) | Weight (kg) | Moment Of Intertia (kg.m²) | Cylinders | Hard Top Jaws | Soft Top Jaws | Gripping Range (Ømm) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| D324 | A11 | 35 | 11.3 | 8506 | 27419 | 33.5 | 1730 | 280 | 7.7 | TC20035 | PD1-21-1 | PE1-24-1 | ø102~ø621 |

| D324 | A15 | 35 | 11.3 | 8506 | 27419 | 33.5 | 1730 | 271 | 7.4 | TC20035 | PD1-21-1 | PE1-24-1 | ø102~ø621 |

If the dimension and specifications change, please take the confirmation drawing as standard.

| Model | Adoptor | A | B | C | D | E | F | G | H | J | K | M | N (max) | O (max) | O (min) | P (down) | P (up) | Q | R | S | T | U | V | X | Y | Reference Drawing |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| D324 | A11 | 610 | 156 | 380 | 60 | 27 | 196.869 | 330.2 | 235 | 31 | 6-M24 | 6 | 122 | 98 | 29 | -7.5 | 27.5 | 0.5 | 25 | 60 | 64 | M30*3.5P | 6-M20 | 67.5 | 180 | Fig2 |

| D324 | A15 | 610 | 156 | 380 | 60 | 27 | 285.775 | 330.2 | 330.2 | 35 | 6-M24 | 6 | 122 | 98 | 29 | -7.5 | 27.5 | 05 | 25 | 60 | 64 | M30*3.5P | 3-M12 | 67.5 | 180 | Fig1 |